Building a 6m "Squalo" Antenna

21 January 2022

Tanner Sterling

I was browsing the Internet for radio antenna ideas and I stumbled across PA3EGH's site with quite a few copper ham radio antenna projects. I saw several pics of the squalo antenna for 2 and 6 meters. I recently moved my 2m/70cm open-stub j-pole to the peak of my house with some new lmr400 to it. I am quite happy with it’s performance, so I thought a 6m project would be a lot of fun. I finally have a transceiver (FT-991A) that will do 6m, and I have yet to check it out. So I decided I would give the 6m copper squalo anteanna a go!

Theory

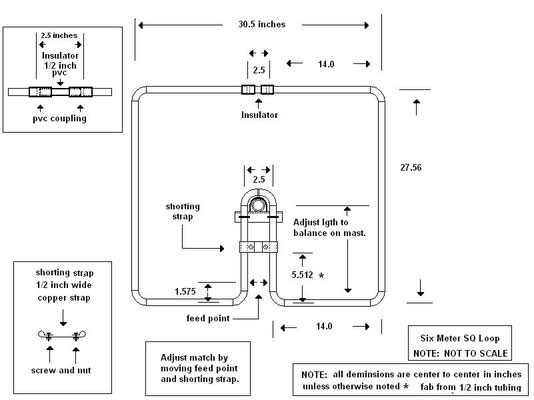

The squalo antenna is a 1/2 wave dipole that is similar to a halo antenna, but instead of being bent into a circle, the squalo is shaped into a square. The dipole is bent around and creates the perimeter of the antenna. The far ends (across from the feed point) do not touch. To provide rigidity, a small piece of CPVC pipe and two collars are inserted in the gap, connecting each side together. Depending on how close the copper pipe ends are separated from one another, a capacitance can be formed that can change the resonant frequency of the antenna. When mounted parallel to the ground, the squalo is mostly an omnidirectional radiating antenna with a horizontal polarization.

Materials

The plans call out for ½” copper pipe, 8 elbows, and some 1/4” CPVC connectors and a short length of CPVC pipe.

Construction

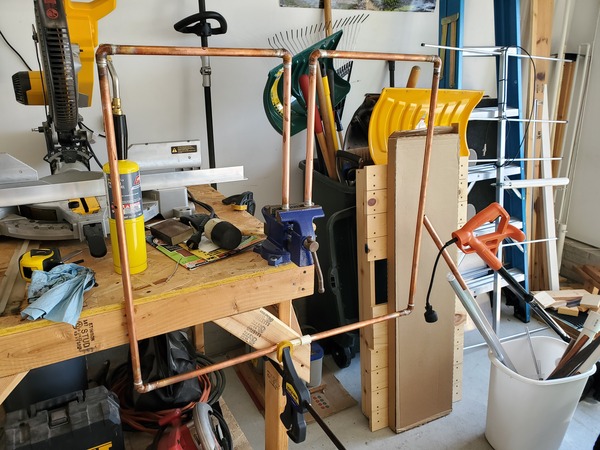

I started with the two outer elbows connected together with the CPVC pieces. I soldered most of the elbows on the concrete ground with small blocks of wood to elevate the copper pipe pieces. I was carfeul to try and keep the antenna square, keep the antenna in the same horizontal plane.

I essentially split the antenna into two identical mirrored pieces when game planning during the construction phase. For each piece, I measured, cut, prepped, and soldered the copper pieces together. Once both identical sides were made, I used the ½” CPVC pieces to fill the “gap” between the two pieces. For the middle piece, the length of the arms is used to balance the antenna. I used a piece of aluminum rod and a square to roughly find the center of mass of the antenna. I found it roughly close to the middle, as one would expect. I made the “end cap” with two elbows and a short piece of copper pipe. I added the cap to the copper pipe arms before soldering them together. I used the aluminum rod again and then cut the arms to balance the antenna where I thought my aluminum antenna bracket would go, approximately 1-3/4” from the inside of the cap.

I then finished soldering the entire antenna together. The antenna was fairly square, but it was just a touch off. I used a bench vice and also a clamp to hold the antenna in square. I then re-heated up the elbows and watched the antenna snap flat. I added a bit of solder back to the connections to keep them solid. I didn’t want to re-heat the connections too much as to not overheat them or compromise their integrity.

Once the antenna was mostly soldered together, it was time to create the antenna mount out of aluminum angle. Once cut to length, I used a drill press to drill the holes for the u-bolts for the antenna arms and the antenna mast.

Tuning

I used a ladder to hold up a temporary antenna mast in order to elevate the antenna to minimize ground losses. For the feed-point, I created a make-shift adapter that consists of battery terminal clamps soldered onto a small piece of RG-58 with a PL-239 soldered on the other end. This method allowed me to easily slide up and down the tuning positions on the copper pipe. I plugged the PL-239 into my Rig Expert AA230 antenna analyzer. This helped me find the sweet spot, if you will. Once found, I marked on the copper pipe where the clamps where. When I bonded the antenna permenantly with the copper strap, I used the "shortest" marking, electrically. I soldered my strap into place, although I'm not sure that was the best idea. It's now extremely hard to tune again and it did not "solder" very well. I would use small screws, washers, and some lock washers instead.

Once everything was now electrically bonded and in place, I used some expoxy and a piece of off-white CPVC to hold the other open ends together, but not electrically. I then sprayed the antenna with several coats of white spray paint from Ace Hardware. I also then followed up with some clear spray coats as well; which gave it extra protection and it is very shiny and pretty.

Once the paint thoroughly dried (several days), I was then able to attach the feedline using a common elec. loop connectors that I first crimped into place and then soldered to make it more permenant. It's an extra strep with crimp connectors, but it is definitely worth it. I've seen way too many crimp-only connectors come apart to ever use them that way alone.

On the Air...

I was very excited to check out the "magic" 6 meter band. I finally got my 6m squalo attached to my gable antenna mount. Initial SWR readings were 1.5 SWR or just slight less. I did find out that this antenna is very narrow-banded however. As I moved up the 6m band, I started using my FT-991A's internal tuner once the SWR was getting closer to 2:1 SWR. Using the auto tuner though, the antenna worked just fine at the top of the 6m band.

Summary

I had a lot of fun building, tuning, and operating with this antenna. It definitely looks great on my small gable mount. I did find out that it was fairly narrow-banded and I would suggest not soldering the strap in place. Overall, this has been a great anetnna and I can't wait to see and be a part of some of the "magic" that 6m can carry. Thank you for reading and 73 friends.

Please email all comments or suggestions to tanner.j.sterling@gmail.com